SDS Platform/Zero Drop Bars/Install

From Unofficial Zero Manual

The police models (SP/DSP) include some drop bars with bracketing to mount law enforcement specific equipment like a siren and flashing lights.

- Both the police versions of these drop bars and less expensive drop bars without the bracketing are available to all owners.

- The width is broad; about 7 inches on the top half (for a total 26" width around the frame there), but they taper to the bottom so lean angle is not affected.

- Zero does not list all drop bar options on their website, but dealers can request them by part number.

- Instructions have not been observed included yet.

- Construction

- Steel tube of 1" outer diameter with a black finish.

- Upper Fastening

- The bars attach to each other via a crosspiece just in front of the frame.

- The crosspiece is held to the frame by shoulder brackets on each side.

- Lower Fastening

- The bars have a flange that bolts directly to collared inserts in the metal skid plate.

- The metal skid plate is provided on the DS/DSR.

- The plastic skid plate provided on the S/SR is swapped for the DS/DSR metal skid plate during installation.

- Install Variations

- 2015+: the frame is predrilled to mount them, but the lower mount varies slightly per model year and may require modification to the belly pan.

- 2014: the belly pan required drilling, and use of Rivnuts. Zero was not cooperative in acquiring, but parts from a downconverted SP were found.

- 2015+ DS,DSR: The skidplate included in the 10-08062XX kit is redundant.

- It is the exact same one already on a factory new DSR, with plastic plugs in the threaded inserts that need removed.

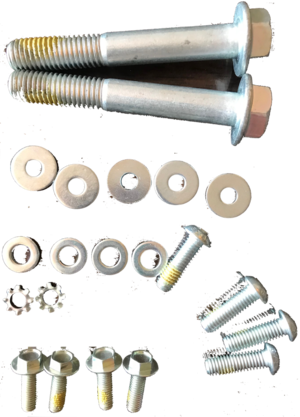

- Parts

- (2) Side bars (left and right).

- (1) Crossmember piece.

- (1) Metal skid plate; identical to DS/DSR original skid plate, and must replace an S/SR plastic skid plate.

- (2) Shoulder brackets (left and right).

- (2) Heavy hex head M10x70mm stay bolts - 30mm thread with 40mm shoulder. Stamped "FMI 10.9" on the head.

- These join the crossmember to the bars through the shoulder brackets.

- (4) Shoulder mount bolts: M5x20mm cap head bolts (replacements can have a 5mm long shoulder that is 6mm diameter).

- (5) Wide washers: 6mm ID, 14mm OD

- (4) Narrow washers: 6.5mm ID, 12mm OD

- (2) Toothed lock washers: 5mm ID

- These may be mistakenly included when recorded? No known application

- (4) Lower mount bolts: M6?x15mm hex head bolts.

- Allen wrenches for M5 and M6 bolts (depends on what is chosen).

- 10mm hex socket wrench for the stay bolts.

- Optional: Plastic rivet removal tool

- Steps

- Pre-2015: Create frame holes for the upper and lower pair of bolts on each side of the frame.

- Installing rivet nuts as Zero started doing for 2015+ frames is a good practice.

- Zero chose M5 rivet nuts with a 5mm deep, 6mm diameter shoulder space above it. M6 might be a more robust choice.

- One pair goes into the rear/top of the angled bar before it comes to the frame shoulder, 30mm between hole centers.

- One pair goes into the side of the belly pan / bash plate. The DS' metal bash plate is more suitable for this.

- S/SR: Remove the original plastic skid plate and install the included metal skid plate.

- Remove the plastic threaded cover inserts in the pair of holes on each side of the bash plate.

- You may need to remove the plate to rotate them out from the inside. Remount after.

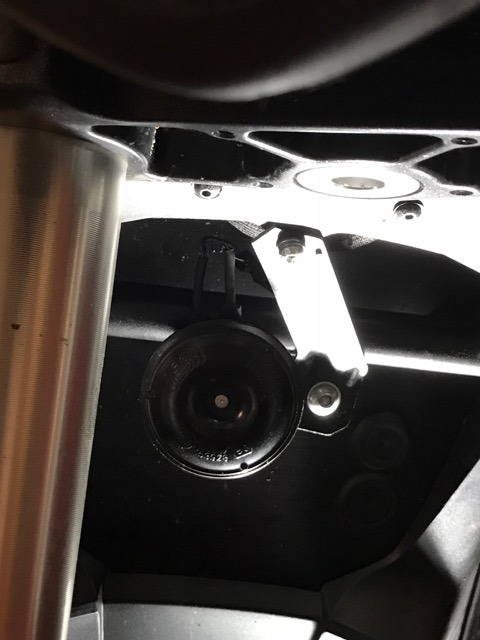

- Detach the horn bracket (via a hex nut and lock nut) and set it aside.

- You may relocate it closer into the front of the frame or move it to the side (no recommendation here).

- DS/DSR: The front fender will interfere with this and the next step. Detach it and set it aside.

- Install the small shoulder brackets on each side of the frame shoulder area, using the pair of holes to anchor the brackets.

- Take the cross member and place it between shoulder brackets.

- Hold the cross member in place by running the M10x70mm bolts through the main holes.

- Attach each drop bar:

- Place the bar against the shoulder bracket with the lower end hanging back but under the bike.

- Thread the M10 bolt through the shoulder bracket into the bar's top opening to support the bar.

- Rotate the supported bar's bottom end to cover the skid plate.

- Thread M6 bolts through the lower end's flange into the collared holes on the side of the skid plate.

- Tighten the bolts (M10 at top and M6 at bottom) in concert.

- The M10 bolt at top could benefit from either a telescoping socket across the bike behind the forks, or a shallow side socket wrench.

- The M6 bolts below can use a hex socket with an extension.

- Re-mount the horn by either:

- Once both crash guard bars are fastened tightly, check and tighten the bolts holding the small shoulder brackets.

- DS/DSR: replace the front fender if you removed it before.

- References