FST Platform/Unofficial Service Manual

Overview

This describes the Zero FST Platform and includes as many service tasks not described (or incompletely described) in the Official Owners Manual as customers have identified.

- Relevant Models: SRF Model and SRS Model.

- Some information might be hearsay or not completely communicated, but attempts have been made to verify as much as possible.

- As with anything in a wiki environment, whatever you undertake with this as a guide is your own responsibility.

Contents

- 1 Overview

- 2 General Information

- 3 General Maintenance

- 4 Frame/Bodywork

- 5 Steering

- 6 Wheels

- 7 Suspension

- 8 Final Drive

- 9 Brakes

- 10 Powertrain

- 10.1 Throttle

- 10.2 Regen

- 10.3 Drive Modes

- 10.4 Motor

- 10.5 Controller

- 10.5.1 Controller Operation

- 10.5.2 Controller Alignment

- 10.5.3 Controller Versions

- 10.5.4 Controller Mounting

- 10.5.5 Controller Uncovering

- 10.5.6 Controller Heatsink

- 10.5.7 Controller Connections

- 10.5.8 Controller Feature Usage

- 10.5.9 Controller CAN Diagnostics

- 10.5.10 Controller Configuration

- 10.5.11 Controller Cover

- 11 Electronic Systems

- 12 Battery

- 12.1 Battery Concepts

- 12.2 Charge Tips

- 12.3 Battery Capacity

- 12.4 Cells

- 12.5 Cell Arrangement

- 12.6 Battery Management System

- 12.7 State of Charge

- 12.8 Battery Storage and Capacity with Age

- 12.9 Battery Temperature Effects

- 12.10 Battery Memory Effects

- 12.11 Rate of Charging and Discharging

- 12.12 Protections

- 12.13 Battery Stress Factors

- 12.14 Battery Longevity

- 12.15 Battery Future

- 12.16 Battery Best Practices

- 12.17 Battery Construction

- 12.18 Battery Removal

- 12.19 Battery Pack Rebuild

- 13 Charging

- 14 Electrical System

- 15 Troubleshooting

Platform

Zero motorcycles benefit from some commonality around the powertrain. The motor, controller, BMS and MBB are more or less shared across all models, along with handlebars and controls.

This is the Gen3 platform listed for the SRF Model and SRS Model.

General Information

VIN

The VIN is inscribed on the front head tube of the frame per the official manual.

See the VIN Guide to understand how the VIN describes your vehicle, as compiled across manual revisions.

Systems

This is a very simplified way of looking at the bike’s systems functions and general purposes, linking to relevant sections.

Mechanical Systems

Powertrain Systems

Energy Systems

Electrical Systems

General Maintenance

Mostly, refer to the Official Owners Manual for regular and general maintenance.

Lift

Some maintenance tasks are better performed with the wheels off the ground.

- The armored pan under the battery that protects onboard charging units is strong enough and positioned well to use a center lift.

- Recommendation

- Using a scissor lift center stand is an easy method to lift the bike.

- Rage Powersports BW-1604A has been spotted at Zero HQ, but other manufacturers make very equivalent stands.

- A center lift is easier than a rear stand to operate solo, and it is more compact than the rear stand although much heavier.

- Location (S Platform)

- Use a center lift under the battery compartment.

- Orient the center stand so that it runs side-to-side to provide lateral stability.

- Place it under the rear of the battery compartment to lift the bike's front and rear equally.

- Place it under the front of the battery compartment to lift the bike's front and leave the rear tire in floor contact.

- Strap the bike securely (through the center frame tube, say) to avoid toppling it.

- Confirmed fits

- Drag Specialties Center Jack (all models) uses a 15/16 hex wrench to raise and lower the lift.

- Generic Lift uses a 7/8 hex wrench/socket; should work for all models, confirmed for 2014 SR.

- Location (X Platform)

- The FXS (at least) has three bolts sticking out from the pan under the bike.

- Orient the center stand so that it runs side-to-side to provide lateral stability.

- You can put a rubber pad on your lift to make it easier to use it over the bolts.

- Confirmed fits

- MSR Pro Lift Stand for the FX, but not other models (even FXS) because of height issues.

- References

- Discussion thread

- Video of DSR lifted by scissor jack.

- Rage Powersports BW-1604A scissor jack unboxing by [E Shattow on YouTube]:

Front Stand

- When To Use

- A front stand is the easiest way to:

- Perform Front Wheel Removal.

- Remove and replace the Belly Pan.

- Spool Stands

- The Zero does not offer axle attachment points for spools for a front stand.

- Steering Head Pin Stands

- 2014+ models(?) have a steering pin diameter of 5/8".

- 2012-2013 Zero models have an 8mm diameter (from a 2013 Zero S report and some checking around), with no vendor match.

- The DS/DSR/FX models' high front fender must be removed (or drilled through) to use a pin for the front steering head.

- Confirmed fits

- Pit Bull offers Pin #7, Front to fit the 5/8" steering pin diameter.

- Pit Bull Hybrid Dual Lift Stand Zero S/SR/DS/FX (Order should automatically include pin #7).

- Verify your steering stem before ordering.

- Front Stand Chart.

| Years | Platform | Front Pin | Rear Pin | Rear Supports | Restraint |

|---|---|---|---|---|---|

| 2013 | S & X | None! (8mm ⌀) | Pin Fitting Only - Zero Motorcycles (Axle: 23-04736) | Trailer Restraint System - Zero Motorcycles (Axle: 23-04736) | |

| 2014 | Pin #7, Front | ||||

| 2015+ | Pin Fitting Only - Zero Motorcycles (Axle: 23-08032) | Trailer Restraint System - Zero Motorcycles (Axle: 23-08032) |

Rear Stand

- Inexpensive Jack Stands and a 2x4

- Will Burk shared his technique Cheap and Easy Motorcycle Lift for raising the rear wheel off the ground with a pair of jack stands and a 2x4:

- Swingarm attachment

- The Zero does not offer swingarm attachment points for spools for a rear stand.

- A rear stand can work if it cradles the underside of the swingarm snugly.

- This can work but takes a little care to operate single-handedly.

- Confirmed fits

- Pit Bull Standard Rear Stand

- Pit Bull Forward Handle Standard Rear Stand

- Haul-Master 1000 Lb. Capacity Motorcycle Swingarm Rear Stand (Harbor Freight)

- Axle Attachment

- Custom Fabrication

- An axle stand can be fabricated, like this Home made rear axle stand on Zero FXS.

| Years | Platform | Front Pin | Rear Pin | Rear Supports | Restraint |

|---|---|---|---|---|---|

| 2013 | S & X | None! (8mm ⌀) | Pin Fitting Only - Zero Motorcycles (Axle: 23-04736) | Trailer Restraint System - Zero Motorcycles (Axle: 23-04736) | |

| 2014 | Pin #7, Front | ||||

| 2015+ | Pin Fitting Only - Zero Motorcycles (Axle: 23-08032) | Trailer Restraint System - Zero Motorcycles (Axle: 23-08032) |

Tools

See the separate Tool Kits article for a curated short list of tools with their purposes.

- NOTE: integrate or meld notes below with that article.

Tools and parts to support your bike

A travel kit for a motorcycle is always a good idea, but Zero doesn't include a default set. They do sell a tool kit which covers many common tasks.

- Tools for Everyday Riding

- Torx T45 for MY2015+ to remove the seat for fuse block access.

- 3mm allen key for tank plastics and headlamp upper mount screws.

- 4mm allen key for headlamp lower mount screws.

- 5mm allen key for the front brake lever and front wheel pinch bolt.

- Tire pressure gauge.

- 10mm, 13mm wrench (or monkey wrench) for belt tension adjustment and front brake calipers.

Consumables

These collect useful spare parts for FST Platform models.

- Spare Parts for Everyday Riding

- 12V fuses (10A, 15A typically).

- Tire patch kit, suitable for tubed (pre-2015 DS or FX bikes) or tubeless tires (all others).

- Cable ties and electrical tape for wiring.

- Spare Parts for Travel

- Belt

- ~$90, only available from Zero.

- Expect to eventually use it as replacement; avoids a delay waiting on delivery.

Pre-Ride Checklist

| Item | What to Check | Look For | Check Off | |

|---|---|---|---|---|

| Tires And Wheels | Tires | Condition | Tread depth, wear, weathering, evenly seated, bulges, embedded objects. | Front & Rear |

| Air Pressure | Check When Cold; Adjust to Load | |||

| Wheels | Spokes | Bent/broken/missing. Check tension at top of wheel: "ring" is okay, "thud" means loose. | ||

| Cast | Cracks or dents | |||

| Rims | Out of round by more than 5mm. Spin the wheel against a stationary pointer | |||

| Bearings | Grab the tire and flex it; no freeplay (click) between the hub and axle; no growl or squeak when spinning. | |||

| Seals | Cracked or torn, no grease | |||

| Brakes | Function | Each brake alone can hold the bike stationary | ||

| Condition | Worn pads or discs | |||

| Controls | Handlebars | Condition | Bars are straight, turn freely, handgrips and bar ends are secure. | |

| Brake Lever / Brake Pedal | Condition | Not broken/bent/cracked; adjusted properly. | ||

| Pivots | Lubricated | |||

| Brake Hoses | Condition | No cuts/cracks/leaks/bulges/chafing/deterioration. | ||

| Routing | No interference or pull at the steering head; no sharp angles; support clamps in place. | |||

| Throttle | Operation | Moves freely; snaps closed. | ||

| Lights & Electrics | Headlamp/Running light | Condition | Turns on; no cracks; mounted securely; clean reflector. | |

| Aim | Just below horizontal and not skewed left or right. | |||

| Tail Lights | Condition | No cracks; clean and bright. | ||

| Operation | Running light always on; brighter with front or rear brake pressed. | |||

| Switches | Operation | All switches function correctly: motor cut-out, hi/low beam, turn signal, hazard switch. | ||

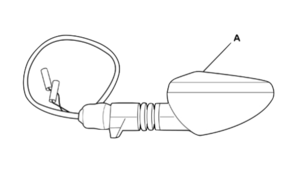

| Turn signals | Operation | No cracks; flashes with left and right turn signal switch usage; resets per switch. | ||

| Mirrors | Condition | No cracks; clean, mount and swivel joints are tight | ||

| Aim | Check/adjust while seated on the bike off the kickstand. | |||

| Wiring | Condition | No fraying or chafing; insulated. | ||

| Routing | No pinching, interference, or pulling at the steering head or suspension; wire looms and ties in place; connectors tight and clean. | |||

| Oil & Fluids | Hydraulic Fluid | Level | Check front and rear reservoirs | |

| Cleanliness | Check whether the fluid is very dark, foamed, or has water | |||

| Chassis | Frame | Condition | No cracks at gussets or accessory mounts; no paint lifting | |

| Steering-Head Bearings | No detent or tight spots through full travel; raise front wheel and check for play by pulling/pushing forks. | |||

| Swingarm Bushings | Raise the rear wheel and check for play by pulling/pushing swingarm. | |||

| Suspension | Front Forks | Smooth travel, equal air pressure/damping, anti-dive settings. | Left & Right | |

| Rear Shock | Smooth travel, equal pre-load/air pressure/damping settings, linkage moves freely and is lubricated. | |||

| Belt | Tension | Check at tightest point | ||

| Alignment | Check position on rear sprocket; spin the wheel to check changing position | |||

| Sprockets | Teeth not hooked or chipped; clean and securely mounted | |||

| Fasteners | Threaded | Tight; none missing; check for corrosion | ||

| Clips and Pins | None broken or missing | |||

| Stands | Side Stand | Condition | No cracks; not bent; cutout switch equipped and working | |

| Retention | Springs into place; tension holds position up or down |

Fastener Maintenance

To maintain the fasteners (bolts and screws), always check for loose or corroding bolts.

- Torque

- For torques, see Fastener Specifications, which gathers all the officially recommended torque and other settings for various fasteners.

- Locking

- Use blue Loctite threadlocker for non-conductive bolts.

- Corrosion

- TODO: recommend a corrosion inhibitor.

Frame/Bodywork

Frame

This describes the frame for the FST Platform.

- Forward Frame

- The forward frame (or main frame) consists of a steel tube trellis, 29mm OD for the main spars, 20mm for the smaller spars.

- Tail Subframe

- The tail subframe bolts to the forward frame and supports the 12V battery, the seat, and of course the tail lighting.

- Powertrain Mounting

- The motor is a structural member joining the swingarm to the frame by heavy bolt fasteners and a pair of brackets labeled "frame doubler".

Forward Frame

The forward frame (or main frame) consists of a steel tube trellis, with two main spars extending back from the head tube.

- Mounting

- The frame joins to the main power pack monolith via a few bolts on each side.

- The frame joins to each of the frame doublers on the outside of the motor at the lower ends of the main spars.

- The frame supports the tank, its contents, and forward plastics.

- The head tube supports the triple tree and forward steering and suspension.

- Measurements

- 29mm OD for the main spars

- 20mm OD for the smaller/truss spars.

Tail Subframe

The tail subframe is a single structure, supporting only the tail, that joins to the forward frame.

- Mounting

- The tail subframe joins to the forward frame via two major pivot bolts and what seem to be 3 anchor bolts below the rider's seat.

- The tail subframe supports the 12V battery, the rider and passenger seat, grab handles, tail rack, and of course the tail lighting.

- The tail subframe also has a plastic enclosure and fairing plastics.

- The onboard charging inlet bracket at the base of the tank seems to join to both the tank support plate and the tail subframe.

Frame Doubler

The frame doublers are a set of circular-oriented cast plates that bracket the motor and join it to the forward frame.

- Mounting

- It joins to the forward frame via ... bolts.

- It supports the rearsets via ... bolts.

- It supports the swingarm via a large circumferential bearing laid into a bracket that the swingarm bolts onto.

Kickstand

Zero's models' kickstands are made from cast aluminum and swings outward from the left side.

There is a safety interlock Hall sensor switch at the pivot that prevents the motor from operating when the kickstand is down.

| Years | Model | Length | Part no |

|---|---|---|---|

| 2013-2014? | S/SR | shorter than the DS/DSR | 20-05660 03 |

| DS/DSR | 10.8" / 275mm | 20-05661 03 | |

| FX | 15.0" / 380mm | 20-05662 03 | |

| FXS | |||

| 2015+ | FX | 13.5" / 343mm | |

| FXS | 11.8" / 300mm |

Both DS and FX kickstands are identical from the spring screw up to the pivot, and should interchange.

All the 2013+ kickstands uses the same pivot pin & spring.

- References

- Re: 2016 FXS Lowered Ride Height OEM Shock, Dual Use Tires, Drop Bars, Hand Guards,

- Help needed: Kickstand "bent"

- Mounting

- 3/8" E clip, Zero part no 90-0283700, also available generically.

- Clevis pin custom, Zero part no 90-0279900.

- Mounting bracket, custom

- Maintenance

- The official manual recommends keeping the pivot greased as necessary with a six-month check interval.

- Problems

- A Loose Kickstand can result from inadequate greasing over time.

This replaces the Kickstand.

See Kickstand Removal and Kickstand Install for now.

- Tools

- Center lift or stand.

- Large flat-blade screwdriver or specialized tool like drum brake spring pliers for spring removal and replacement.

- E-clip tool (or needlenose pliers) for the 3/8" E-clip.

- Steps

- (When replacing) Remove the allen bolt securing the springs to the old kickstand.

- (When replacing) Transfer the 2 bronze bushings from the old kickstand:

- Remove the 2 bronze bushings from the old kickstand.

- Clean and grease bushings.

- Insert bushings into new kickstand and replace chamfered bolt with springs.

- My chamfered bolt was not very tight and I assume it was being held in from the spring tension.

- I went to tighten it all the way in but that seemed to push the springs out too far.

- I put blue Loctite on it and threaded it about half way in.

- I will check this after a few rides to ensure it does not fall out!

- Place the new kickstand onto the pivot.

- Install the pin and spring

- Pin Before Spring

- Insert the pin.

- Raise the kickstand to its stowed/horizontal position.

- This minimizes the amount of force/extension to install the new spring.

- Install the spring over the kickstand hook with a suitable tool (see tools requirements).

- Spring before pin

- Have the pin and a tapered punch that fits nicely in the hole ready to go.

- Clean the pin and apply fresh grease to it.

- Hook the springs onto the frame, grip the kickstand with both hands, put your shoulder into the bike so it won’t tip.

- While pushing straight down on the kickstand, get it onto the frame and insert the tapered punch.

- Now raise the kickstand into the stowed/horizontal position.

- Remove punch.

- The hole will be almost aligned.

- Insert the pin as far as it will go, mine stopped at the frame.

- With the kickstand still in the up position, tap the bottom of the kickstand pivot area up towards the frame with a dead blow hammer while pushing the pin in.

- This should align the hole and allow the pin to go right in.

- Insert the pin and fasten it with a new 3/8" E-clip.

- Note: This is the most difficult and dangerous part of the job.

- Use eye protection while doing this and ensure your hands won't be damaged if the spring flies back while getting it over the hook.

- Focus on applying steady force with as much leverage as possible to extend the spring back along the swingarm.

- One trick is to use a strong line looped through the hook as a pulley.

- Another trick is to bend the spring enough back and forth to insert pennies between the coils, which holds it in an extended position.

- Then loop the spring over the hook and pull the pennies out with pliers.

- Check the operation of the kickstand a few times.

- Ensure that it operates smoothly.

- Ensure the kickstand sensor detects the position of the kickstand, by checking the interlock indication on the dash while the bike is keyed on.

- Put the kickstand down before letting the motorcycle off the lift to rest on it.

- Tools

- Center lift or stand.

- Large flat-blade screwdriver or specialized tool like drum brake spring pliers for spring removal and replacement.

- E-clip tool (or needlenose pliers) for the 3/8" E-clip.

- Steps

- Place the motorcycle on a center lift or stand.

- Spring Before Pin

- Pull the spring off of the kickstand hook with a large flat blade screwdriver or a specialized kickstand spring release tool.

- Raise the kickstand to the stowed/horizontal position, to reduce spring tension.

-

Warning:

Warning: Be extremely careful working with the kickstand spring as it is under high tension. - A specialized tool makes this easier.

- Remove the pivot pin.

- Remove the kickstand.

- Pin Before Spring

- Remove the pivot pin.

- Pull the E-clip off of the inside of the pivot.

- Raise the kickstand to the stowed/horizontal position, to reduce spring tension.

- Go to the left side of bike.

- Wiggle the kickstand while tapping the pivot pin from underneath with for example a soft faced hammer.

- Continue to wiggle the kickstand while gripping the pin until it slides out.

- Often comes out by hand with a rag.

- Carefully slide kickstand away from frame and unhook springs from frame.

- The kickstand will still be under some tension from both springs, inner and outer.

Footpegs

Zero footpegs are cast aluminum pieces, mounted on identical hinges so are interchangeable across models.

- Mounting

- The mount bracket uses a custom clevis (10mm ⌀ with 40mm working length and 45mm overall length), secured with a retaining E-clip (3/8" or 9.5mm inner ⌀).

- Repair

- The footpegs' aluminum casting is relatively brittle, and the pegs tend to break rather than bend.

- See Footpeg Replacement.

- Reference

- "The pegs are the exact same part used by the Buell XB models (except for the Ulysses), and as the passenger pegs on the 1125R models. They are "sacrificial lambs" to protect the rest of the frame."

- "Any pegs made for the 2008-2009 Suzuki RMZ450 should fit the DS,DSR,FX models"

Rider Footpegs

These Footpegs are only installed for the rider, versus Passenger Footpegs.

|

Rider Footpeg Removal

- Tools

- Snap Ring / E-Ring pliers (needlenose pliers are a common if less easy substitute).

- (Optional) 7mm Allen key to remove the clevis bracket from the frame.

- Steps

- Gently spread the gap in the retaining E-ring using the pliers until it slides over the end of the pin, and remove it.

- This clip is on the lower end of the footpeg retaining pin.

- Pull the retaining pin up and out.

- Hold and pull the pin spring and footpeg as the pin comes out.

- (Optional) Use the 7mm Allen key to remove the bolt through the clevis bracket that fastens it to the frame.

- References

- How to Remove Zero Footpegs + Relocation Ideas by NewZeroLand on Youtube

Passenger Footpegs

Passenger footpegs are ergonomically identical to the sport rider footpegs, since passenger geometry requires reduced legroom and a forward foot angle on the rest.

- They are not spring-loaded.

- They lack the hole for the feeler stud that the rider footpegs use.

- Mounting

- The passenger footpegs hinge on the passenger footpeg bracket which mounts to the frame.

- They use an additional installed pin and custom clip plate to secure the passenger pegs in either the stowed or out position (vertical and horizontal, respectively).

Passenger Footpeg Removal

- Tools

- Snap Ring / E-Ring pliers (needlenose pliers are a common if less easy substitute).

- 13mm hex side or socket wrench (for the bracket).

- Steps

- Gently spread the gap in the retaining E-ring using the pliers until it slides over the end of the pin, and remove it.

- This clip is on the lower end of the footpeg retaining pin.

- Pull the retaining pin up and out.

- Hold and pull the pin spring and footpeg as the pin comes out.

- (Optional) Remove the bracket

- Loosen the upper bolts mounting the footpeg brackets to the frame.

- S-platform: Reaching these bolts from the rear is easiest since they are on the inside of the frame.

- Loosen the lower bolts mounting the footpeg brackets to the frame.

- S-platform: These face the motor and allow very low overhead.

- A side wrench is recommended, and a ratcheting version preferred.

- S-platform: These face the motor and allow very low overhead.

- Remove the bolts and then the brackets.

- Loosen the upper bolts mounting the footpeg brackets to the frame.

- References

- How to Remove Zero Footpegs + Relocation Ideas by NewZeroLand on Youtube

Seat

The seat is provided in a rider seat section and a passenger seat section.

- The passenger seat can be released with the key, revealing a small tray (for tools, perhaps) and hooks for locking a helmet on each side of the tail.

- The rider seat can be released by Torx (T15?) bolts that are at the front of the area under the passenger seat.

The SR/S seat differs from the SR/F seat, apparently in being broader and longer especially for the passenger.

Seat Removal

This removes the seat from SDS Platform bikes.

- Notes

- Unload any luggage racks before taking the seat off for an extended period of time to avoid stressing the racks.

- When luggage racks are installed, the seat bolts are load bearing (or at least damping).

- An M8-1.25×55mm socket cap bolt with a 6mm Allen head can be used if the kit bolt is lost.

- Tools

- 2015+: T45 Torx wrench (for seat bolts).

- 2013-2014 (with top or side racks): 5mm Allen key (for seat bolts).

- Steps

- When luggage racks are installed Remove the top case and/or side cases to ensure the rack is unloaded.

- Remove the M8-1.25×55 seat bolts.

- Push the seat down and forward as needed to help ease out the bolts.

- Pull the seat back a couple of inches and then upwards.

Seat Install

This installs the SDS Platform models' seat.

- Tools

- 2015+: T45 Torx wrench (for seat bolts).

- 2013-2014 (with top or side racks): 5mm Allen key (for seat bolts).

- Steps

- When luggage racks are installed Remove the top case and/or side cases to ensure the rack is unloaded.

- Place the seat on the tail slightly to the rear of where it will sit.

- Ensure that the pan's horn-shaped catches will slip under the frame's Y-shaped centerpiece pins.

- Push the seat forward and down to sit in place.

- Visually align the holes of the seat bracket with the seat bolt holes.

- Align the seat's bracket with the frame holes to avoid wear.

- Align the seat's tabs between the frame rails to avoid stressing the seat pan and marring the frame.

- If the top rack is installed, too, check the alignment of that as well to avoid wear trying to thread the bolts.

- Insert the seat bolts, gently engaging while checking for cross-threading.

- Check for alignment again while the bolt head encounters the seat bracket.

- Press down and forward on the seat as needed to help align and tighten the bolts.

- Tighten the bolt head against the frame surface to hold it in place but do not over-tighten.

- When luggage racks are installed Re-install the top case and/or side cases.

Panel Material

FST Platform/Bodywork Material

Tank Plastics

Tail Plastics

Tail Plastics Removal

FST Platform/Tail Plastics Removal

Steering

Ignition Lock

The ignition lock operates the Ignition Switch.

- Location

- The ignition lock is mounted on the tripe clamp top in the center between the steering head and the dash.

The Ignition Switch connects to a ZADI motorcycle lock with a steering lock feature and parking light enable (although the parking light enable is not connected on the Zero).

- Key Blanks

- Key blanks can typically be ordered from a dealer.

- Key blanks appear to be available generically as JMA ZA9P1 FOR ZADI ZD23RCP.

- In USA, calling them "Triumph" keys may help a locksmith find the right blank.

- Maintenance

Occasional lock lubrication is recommended, and inspection of the wires for startup enable on the underside of the lock for reliability.

- Troubleshooting

- See the faulty ignition switch troubleshooting guide for issues with this.

Tank Lock

The tank lock on the FST Platform is accessed on the left side of the tank, and is keyed the same as the ignition and the seat lock.

Mirrors

- Design

- Pre-2015 (Gen1) Zeros use an angular mirror with a ball mount joint that allows rotating the mirrors 360 degrees.

- Many riders turn the mirrors upside down for a little wider visibility around the shoulder/arms.

- 2015+ (Gen2 and Gen3) Zeros use a mirror stalk with an inboard ball mount with about 30 degrees of freedom from the stalk.

- Mount

- Zero mirrors are mounted from the handlebars with Yamaha/Ducati-style bolt fitting.

- The bolt/thread specification is M10x1.25, left-hand-threaded on the right side and standard right-hand-threaded on the left side.

- Maintenance

- (pre-2015) Check that the set screw holding mirror position holds it firmly.

- Use a corrosion inhibitor or thread-locker for the set screws and the mount threading since these are weather-exposed.

See Third-Party Mirrors for workable/tested replacements.

Handlebar

Zero's models all steer with a handlebar.

- S/SR and FXS models share a shorter, sportier handlebar shape.

- DS/DSR and FX models share a wider, straighter handlebar shape.

- Both S/FXS and DS/FX style handlebars are standard through-bars.

- Diameters

- 1 1/8" (28mm) ⌀ center bar.

- 7/8" (22mm) ⌀ outer bar.

| Models | Years | Width | Rise | Pullback |

|---|---|---|---|---|

| S,SR,FXS | 2013-present | |||

| DS,DSR,FX | 2013-present | |||

| SRF,SRS | 2020-present |

- Control-Indexing Holes

- (1) 3/16" ⌀ on the left for the switchgear, 6.5" from the end of the bar.

- (1) 3/16" ⌀ on the right inner for the throttle, 7 3/16" from the bar end.

- (1) 5/32" ⌀ on the right outer for the switches, 6" from the bar end.

- References

Handlebar Clamps

- The SDS and XMX platform handlebar clamps are 2" by 1 1/8" (28mm) for the entire line of models, clamped with M10 cap screw bolts (35mm length; possibly 50mm?).

Handlebar Switch Assemblies

- The switch assemblies are fastened with TT20 (1/4") tamper-resistant Torx bolts through the underside.

Handgrips

Handgrips have a Zero logo on them but otherwise are reasonably good stock grips for the 7/8" (22mm) handlebar width at the end of the bars.

Bar Ends

For 2014+ models, any bar end accessories that match the 14mm inner diameter will fit.

- The stock bar ends are round plastic bumpers held in by plastic threads, so can be removed with a little twisting and pulling.

- 2013 models

- Bar ends are covered by the grip so are not easily changed without changing the grips.

- Zero did offer heated grips for these models but dropped them after changing the bars in 2014.

Brake Lever

Zero motorcycles have a right-hand lever for the front brake, as is common for motorcycle designs.

- Primary adjustment

- The brake lever has a dial for adjusting the lever position relative to pad pressure and rider finger reach.

- Set it however lets you operate it comfortably and safely.

- Brake Light and Regen Switch

- A set screw on the inside of the lever adjusts how a micro-switch is depressed.

- The micro-switch is what activates the rear brake light and the "braking regen" mode at the same time.

- Any adjustment or replacement of the brake lever should be followed by recalibrating this set screw to get the desired effect.

- Too much free play and the switch will activate when going over bumps and result in a slightly jerky ride.

- There is some guidance on how to adjust this: Brake Lever Adjustment to Regen Before Pad Contact.

- NOTE: It seems like there's small difference in how this set screw is secured in stock lever compared to replacement lever (2016 SR), even though they look identical.

- I wasn't able to adjust this screw on stock lever, however replacement lever adjusts with no issues.

- You will need 7/64 SAE hex key to adjust.

- Use some light threadlock compound (Blue Loctite will do) to fix the set screw in the desired position if it seems to move too freely out of the desired range.

- References

- Adjustment

- See Front Brake Lever Adjustment

- Removal, Repair

- See Front Brake Lever Replacement

Triple Clamp

Steering Head

Steering Head Bearing

FST Platform/Steering Head Bearing

Front Fender

Wheels

Wheel Maintenance

Tire Pressure Check

Maintain minimum pressure per the official manual.

- General guidelines

- Higher tire pressures help stability and reduce rolling resistance with a passenger or a lot of luggage, but lower pressures help on rougher/gravel surfaces.

- Excessive tire pressure can make the tire too sensitive to sharp debris or potholes, and increases the risk of a puncture.

- 45psi is where this definitely becomes a concern; modulate depending on your riding, and definitely use much lower pressures for offroading.

- Official recommendations are for cold tires, which means when they haven't been ridden in a few hours.

- As tires warm up from riding, pressure increases due to the interior air heating from friction and mechanical work on the tire by the road against the wheel.

Front Wheel

Front Wheel Removal

- Video Instruction

- Zero DS front wheel removal by Nigel Morris on YouTube:

- Zero Motorcycles: Front Wheel Removal 2016 DSR by E Shattow on YouTube:

- Tools

- 6mm Allen Wrench - Axle bolt (M17)

- 5mm Allen Wrench - Pinch

- 13mm Socket - Brake calipers

- Steps

- Loosen both brake caliper bolts using the 13mm socket.

- Loosen both right pinch bolts using the 5mm allen wrench.

- Alternate slightly, turning each counter-clockwise.

- Loosen the axle bolt using the 6mm allen wrench.

- Loosen both left pinch bolts using the 5mm allen wrench.

- Alternate slightly, turning each counter-clockwise.

- Securely lift the front wheel.

- Remove both brake bolts using the 13mm socket, and lift and secure the brake caliper without stressing the brake lines.

- Continue to back off the pinch bolts, but do not remove, using the 5mm allen wrench.

- Remove the axle bolt and outer spacer using the 6mm allen wrench.

- Replace the axle bolt with the 6mm allen bolt, turning several turns inward, without the outer spacer.

- Push on the axle bolt while encouraging the left side of the axle out.

- Support the wheel to reduce binding!

- Remove the axle.

- Remove the wheel.

Front Axle

- TODO measurements

Front Tire

See Stock Tires.

Front Bearings

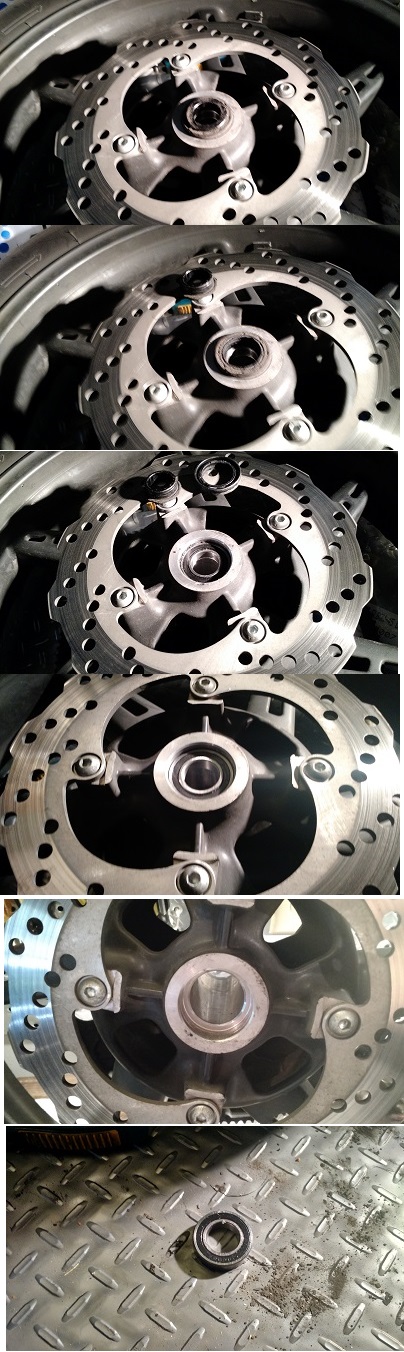

Front Bearing Replacement

This replaces the front wheel bearings on Gen2 models.

- Tools

- 6mm Allen Wrench - Axle (M17)

- 5mm Allen Wrench - Pinch

- 13mm Socket - Brakes

- Bearing Press Tool/Kit

- Steps

- Remove the Front Wheel

- Remove the spacers, then the dust seals, from each side and clean.

- Press the bearings out from the opposite side.

- A socket extension works well, alternating around the perimeter.

- Clean the inner wheel.

- Press the new bearings in, aligning with the inner axle tube.

- A large socket works well to press only on the outer bearing.

- Replace the dust seals.

- Return the wheel to the bike.

- Aligning the axle with the spacers, press the axle back into the forks.

- Expand the brake calipers to prepare for remounting.

- Remount brake caliper with the 13mm socket to the correct torque.

- Return the outer spacer and make the axle bolt snug with the 6mm allen wrench.

- Alternate tightening each 5mm pinch bolt.

- Ensure proper wheel movement.

- Tighten left pinch bolts to the correct torque using the 5mm allen wrench.

- Tighten the 6mm Axle bolt to the correct torque.

- Tighten right pinch bolt to correct torque using the 5mm allen wrench.

- Ensure smooth movement.

- Pump the brakes to return to proper action.

- Lower the front wheel.

- Confirm torques.

- Test ride!

- Reconfirm torques.

- Paint the bolt heads to so that any loosening is detectable.

Rear Wheel

Rear Tire

See Stock Tires.

Rear Wheel Removal

Pulling out the axle and removing the rear wheel is straightforward; the complexity is in re-assembly: see Rear Wheel Install.

- Items to note for re-assembly

- Note how the caliper sits against the swingarm.

- Note the order and arrangement of the spacers.

- Video Guide

- Zero Motorcycles: Rear Wheel Removal 2016 DSR by E Shattow

- Tools

- 27mm socket

- Breaker bar

- Instructions

- Place the motorcycle on a lift or rear stand so the wheel spins freely.

- Mark/photograph where the alignment marks reside on each side of the axle for re-alignment when re-installing the wheel.

- Loosen the rear axle nut on the right side (27mm) with the breaker bar.

- Remove the rear axle nut.

- Pull the axle part-way out so that the wheel can be moved forward enough to loosen the belt.

- Pull the belt off of the rear sprocket and let it hang outside of the swingarm slightly to avoid interfering with the wheel.

- Pull the axle through the wheel from the left side.

- Pay attention to the brake caliper: it's attached via the axle, and when the axle is removed the caliper, etc, will come loose.

- Set aside the spacers with alignment marks, noting which goes on which side.

- Set aside the axle and axle nut.

- Pull the wheel out behind the swingarm.

- The license plate tail holder will likely require rolling the wheel out at an angle to clear it.

Rear Wheel Install

Re-installing the rear wheel requires somewhat careful fitment of the wheel, spacers, ABS sensor (2015+), and brake calipers within the swingarm.

- Pay attention while removing the wheel to have this arrangement in mind to avoid confusion.

- Any play in the caliper position or the wheel itself could have a dramatic and damaging effect on the motorcycle while riding.

- Tools

- 27mm socket

- Torque wrench set to 75ft-lbs (102Nm)

- (Optional) rubber mallet to nudge the axle

- Instructions

- Also see Belt Adjustment

- Ensure that the axle has grease applied if it is dry, to minimize friction and wear against it under load.

- Push the axle through the alignment bracket and left swingarm until flush on the inside of the left swingarm.

- Place the rear brake caliper holder onto the right swingarm.

- For 2015+ models, place the ABS rear wheel speed sensor on the inside of the rear brake caliper holder.

- Route the wire feeding the speed sensor around the caliper holder bracket and ensure that the sensor and wire will install without tension or excessive bending.

- Roll the wheel into position inside of the axle.

- Ensure the speed sensor on the right side mates with and covers the rear wheel bearing before it aligns with the rear brake caliper holder on the right side, as this "sandwiches" together.

- Ensure that the brake calipers are pushed to maximum expansion, then place them around the rear wheel brake disc on the right side.

- Push the axle through the wheel by hand or use a rubber mallet to gently nudge the axle through the wheel.

- You may need to give the wheel a wedge underneath to rest on to minimize any stress on the axle while aligning it fully.

- Align the right side of the wheel with the swingarm axle hole and brake caliper holder on the right side.

- Again, manually push or nudge with a rubber mallet the axle through the speed sensor, rear brake caliper holder, and right swingarm.

- Run the belt over the rear sprocket.

- Center the belt over the sprocket so it has about 1mm on either side.

- Ensure that all components are aligned correctly before attempting to tighten the axle or even before mating the left axle end with the swingarm (which tightens the belt).

- Place the axle nut onto the right side of the axle by hand.

- Note the alignment of the left and of the axle's rectangular tabs; hold it in a horizontally aligned position so that tightening the axle nut places it inline with the swingarm slot.

- Tighten the axle nut (27mm) with the torque wrench to 75ft-lbs.

- Ensure the alignment of the axle head on the left side is horizontal and pulls the belt under tension smoothly.

- Check belt tension per the belt adjustment procedure.

Rear Bearings

Rear Bearings Replacement

- Rayivers on Wheel bearing replacement ('14 FX, 6904 bearings)

- Removal was pretty straightforward with a Motion Pro blind bearing removal kit.

- Pullers like these are the only way I know of to remove wheel bearings without risk of damage to the hub or center spacer

- They pull against the small chamfer on the inner-race I.D.

- Greg Hassler reports

- "I use my brake caliper piston puller, 20mm size works great." https://www.klsupply.com/general-equipment/brake-caliper-pist-puller-set-35-6885.asp

- Togo found this tool to work well for 6904-2RS on 2014 Zero SR

- https://smile.amazon.com/Wheels-Manufacturing-Sealed-Bearing-Extractor/dp/B00NIPRNA4/

- See Also

Suspension

Front Suspension

Zero's motorcycles all feature telescoping fork front suspension.

Front Suspension Specs

| Fork | Shock | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Years | Manufacturer | Description | Material | Model | Part# | Travel | Measurements | Oil | Material | Part# | Measurements |

| 2009-2010 | FastAce | DS/X | BDA53AR (discontinued) | ||||||||

| 2012-2013 | 38mm (from Zero website/manual) inverted forks with adjustable compression and rebound damping |

6061-T6 Forged Aluminum (per this thread) Chrome-Moly inner tube; Alloy steel spring wire |

S | ALX07RC (discontinued) 22-05418-03

|

140mm | Compression 12 clicks; Rebound 21 clicks |

6061-T6 Forged Aluminum (per this thread) |

BDA58RC (discontinued) | |||

| DS |

(APX05RC? or APX10AR? (discontinued)) |

7.00 in (178 mm) | clarification?

|

BFA57RC (discontinued)) |

| ||||||

| FX/MX/XU | XU - ALX07RC AP18A0179-B002 22-02749-01 |

|

|||||||||

| 2014 | 43 mm inverted forks with adjustable compression and rebound damping |

6061-T6 Forged Aluminum (per this thread) Chrome-Moly inner tube; Alloy steel spring wire |

S/SR | 6.25 in (159 mm) |

6061-T6 Forged Aluminum (per this thread) |

BDA58RC (discontinued) | |||||

| DS | APX16RC - 22-06867-05

|

7.00 in (178 mm) | Compression 11 clicks; Rebound 20 clicks | BFA57RC (discontinued)) |

| ||||||

| FX | 230mm | ||||||||||

| 2015-2020 | Showa | 41 mm inverted cartridge forks, with adjustable spring preload, compression and rebound damping |

|

S/SR | 6.25 in (159 mm) |

|

|

|

|||

| DS/DSR | 7.00 in (178 mm) | ||||||||||

| FX |

|

|

|

22-05879-02 |

| ||||||

| FXS | |||||||||||

Fork Oil Change and Spring Replacement

- Fork Oil Level Note

- Measure from outer tube end to oil surface (Condition: spring, spring joint, spring collar, seat rubber, slider, fork bolt are removed and dust seal touches axle holder)

- Reference

- FastAce fork oil change / spring replacement+ part 2 by Ray Ivers

- Tools

- 7mm Allen wrench for riser bolts.

- Steps

- Put the motorcycle on a stand.

- Remove the risers and handlebars using a 7mm Allen wrench.

- Loosen the fork caps, front axle, and brake caliper bolts while the front wheel is on the ground.

- Fork cap / spring removal...

- Oil change...

- Fork spring / cap replacement...

- Notes

| What | Torque | Bolt |

|---|---|---|

| Handlebar clamps | 15 ft/lb | M8 |

| Handlebar risers | 25 ft/lb | M10 |

| Triple clamps (all) | 15 ft/lb | M8 |

| Fork caps | 15 ft/lb | M46 |

| F caliper bolts | 18 ft/lb | M8 |

| F axle end cap | 15 ft/lb | M8 |

| F Axle clamps | 9 ft/lb | M6 |

Fork Cartridge Revalving

Fast Ace fork revalving by Ray Ivers

The procedure is described in great detail for FastAce (2013-2014) suspension but could be adapted for the newer Showa suspension.

Verify Fork Spring Rate

- Reference

- How to Verify Fork Spring Rate

- Tools

- A tip-tie long enough to wrap around the fork tube.

- Steps

- Add a zip-tie to the the fork tube.

- Make sure it is snug so it stays in the place it was last pushed too.

- Once the zip-tie is on the fork tube, you push it up to rest it against the upper fork.

- Measure bike sag (unloaded)

- Lift the front fork off the ground and measure the gap (zip-tie to fork gap) created by the front weight of the bike.

- Measure rider sag (loaded)

- Now push zip-tie back up the fork, then sit on the bike and raise your feet so all of your weight is carried through the suspension.

- Then carefully dismount and put kickstand down.

- Measure the gap (zip-tie to fork) created by your weight.

- Add this gap measurement to the bike sag measurement, this is the total sag.

- This measurement should be around 25% of the working range of the front suspension.

- Now that is a guideline; it can be higher or lower than 25%.

- It depends on what is happening when you are loading up the suspension (upper end).

- Checking the upper end by using the zip-tie.

- After riding, check the location of the zip-tie: the gap from the fork to the zip-tie.

- Lets say the measurement is 5". Then you would know the total max travel used was 5" + bike sag measurement.

- That total measurement should never equal the total suspension travel amount (6", I think based on your posting).

- If it equal, then you are bottoming out. Increase the preload and see if this keeps you from bottoming out.

- If you use max preload and are still bottoming out, you will need stronger springs.

- If you find you are only using 75% to 80% of the max suspension travel, you can reduce the preload spacer length some or you can live with this.

- If you are only using ~50% or less of the suspension travel, your springs are probably too stiff. You should swap springs to a lower rate spring.

Rear Shock

Zero motorcycle models use a single shock absorber rear suspension, joining the Swingarm to the Frame.

Rear Shock Mounting

The rear shock fastens to the Swingarm's right side arched arm.

The upper mount reaches the frame ahead of the tail area.

Rear Shock Specifications

| Years | Brand | Model | Description | Media | Specs | Models | Travel | Length |

|---|---|---|---|---|---|---|---|---|

| 2013-2014 | FastAce | BDA58RC | Piggy-back reservoir shock with adjustable spring preload, compression and rebound damping |

|

S/SR | 6.35 in (161 mm) | 10.25-10.5 in (260mm) | |

| DS | 7.03 in (179 mm) | |||||||

BFA57RC

|

|

FX | ||||||

| 2015-2020 | Showa | 40 mm piston, piggy-back reservoir shock with adjustable spring preload, compression and rebound damping | S/SR | 6.35 in (161 mm) | ||||

| DS/DSR | 7.03 in (179 mm) |

Rear Shock Adjustment

- Notes

- The Official Manual section on Rear Shock Adjustment illustrates how to measure preload and check sag.

- Compression

- The official manual's description here is adequate and this can be done readily by hand on the right side of the bike at the top of the shock.

- Rebound

- The adjustment knob is at the bottom of the shock facing rear, as described in the manual, and can be worked by hand or with a wrench with a careful reach into that area.

- Spring Preload

- The official manual illustrates the collar and procedure for spring preload adjustment, but does not recommend a specific tool, and there are clearance issues in that area for tools.

- The adjuster sleeve diameter is 58mm (2.3").

- A Stockton spanner wrench was found to be suitable for the job if modified as follows (per 2017 DSR Showa rear shock spanner wrench):

- Grind the nose of the wrench to fit the notches.

- Bend the wrench a couple of degrees to clear the Sevcon motor controller fins.

- Obviously, a better solution is still worth seeking.

- A small suspension wrench / ER collet spanner size 30/32 can be use even with the lack of clearance

Final Drive

Swingarm

The swingarm supports the rear wheel and pivots around the motor centerline.

- Mounting

- The swingarm joins to the frame doublers via large diameter bearings and a kind of bracket that it bolts to.

- The rear shock connects to the right side of the swingarm crosspiece, on the hump of an arch, making the swingarm asymmetrical.

- The swingarm has threaded holes (M8x1.5mm pitch) for rear stand spools.

- The swingarm supports the rear axle with an adjustment slot for belt tensioning and alignment.

Rear Axle

The rear axle is hollow, threaded on the right side and capped on the left for swingarm fitment.

| Years | Inner Diameter | Outer Diameter | Pitch |

|---|---|---|---|

| 2013-2014 | |||

| 2015+ | 11mm | 20mm | 1.25mm |

Removal

This removes the Rear Axle part of Rear Wheel Removal.

- Tools

- 27mm socket

- Breaker bar

- Instructions

- Place the motorcycle on a lift or rear stand

- Raise just enough that the rear wheel spins freely.

- Mark/photograph where the alignment marks reside on each side of the axle for re-alignment when re-installing the wheel.

- On the right side, loosen the rear axle nut (27mm) with the breaker bar.

- Remove the rear axle nut.

- Pull the axle part-way out so that the wheel can be moved forward enough to loosen the belt.

- Pull the belt off of the rear sprocket.

- Let it hang outside of the swingarm slightly to avoid interfering with the wheel.

- From the left side, pull the axle through the wheel.

Install

To replace the rear axle, see rear wheel replacement.

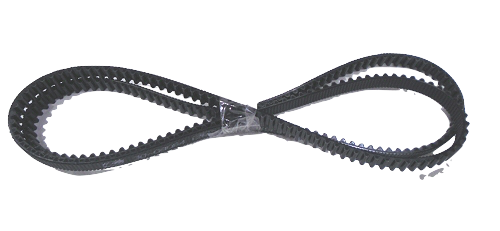

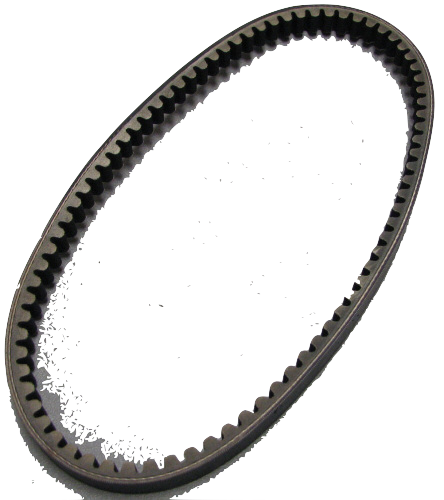

Belt

Zero uses a belt for primary transmission of torque to the rear wheel. It's quiet and lightweight but is a proprietary design that can wear out. If you plan to put a lot of miles on a Zero or risk the belt often, buy a spare belt ahead of time and mind its maintenance.

Belt Risks

Drive belts fail by snapping or by stripping the teeth.

- On Landing

- The most common situation for a belt snap is when going over a major bump or jump where the rear wheel leaves the ground.

- If, while airborne, the throttle is not immediately relaxed, the rear wheel will rapidly spin up.

- A wheel that is moving extremely quickly in the air will get jerked back to its regular speed on landing. This is transmitted to the belt through the rear sprocket and can easily strip teeth.

- From Debris

- Gravel or sand that gets thrown between sprocket teeth and the belt will force the belt to expand quickly under load, and can cause it to snap.

- Reportedly, sand is a much more reliable path to belt failure than gravel.

- The sprocket tooth design is meant to deflect gravel to the inside of the swingarm towards the wheel.

- The bike has an upper debris guard made of soft ABS plastic, but does not have a lower guard.

- From Mis-Alignment

- An unaligned belt can wear really badly and break sooner.

Belt Specifications

Zero's final drive is a custom-designed Gates HTD (high torque drive) Poly Chain Carbon toothed carbon fiber belt.

- It's never been available outside of Zero's parts system.

- It's been the same part for 2012-2016 models.

- 2017 models shifted to a wider belt that can accommodate more torque/loading.

| Years | Width | Pitch | Models | Sprockets | Number of Teeth | Length | OEM Part No. | Photo |

|---|---|---|---|---|---|---|---|---|

| 2010-2011 | 14mm | 8mm | S/DS | 98T / 28T | 200 |

|

||

| 2012-2016 | S/SR | 132T / 28T | 220 |

|

| |||

| DS/DSR | 130T / 28T | |||||||

| 2017- | 17mm | 14mm | S 13.0 | 130T / 28T | ||||

|

90T / 20T | 158 |

|

| ||||

| 2020- | 20 | 11 | SRF | 90T / 20T | 151 |

|

- Part

- Gates GT Carbon, 14mm wide, 8mm pitch, 220 teeth. It's only available from Zero.

- P/N's are 30-03673 ("Belt Drive, 220T, 8mm Pitch, 14mm Wide") and also 30-08084 (same belt w/new Zero logo).

- One rough match for reference: Gates 8MGT-1760-12 Belt

- Another Gates product page that highly indicates a product/technology match: Poly Chain® GT® Carbon™ synchronous belts per Gates drive belts (EMF Thread)

Belt Tension Check

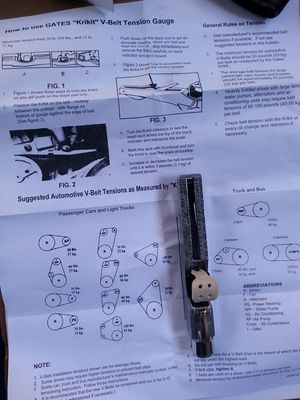

- Krikit Tension Gauge

Zero recommends the Gates Krikit belt tension gauge to check belt tension.

- Video Guide

- MostlyBonkers made a How-to video:

- Tips

- Turning the back wheel backwards before measuring will give different readout compared to turning the wheel forwards before measuring using the same spot.

- The difference may be significant to the (pre-2017) 20-30kg belt tension specification.

- For wide-belt 2017+ models, the tension specification is very wide (~25-75kg) and thus has a lot of leeway but seems worth a rotational check anyway.

- The center of the belt can be reached from below, without removing the mudguard.

- This is described as a note in 5.14 in the 2015 manual

- Ensure the blue indicator arm is pressed down.

- Place the gauge in the center of the belt span, such that it is aligned longitudinally with the belt length.

- Place a finger on the blue pressure pad and depress this pressure pad.

- Keep pressing the blue pressure pad until you feel and hear a distinct 'click'. When this 'click' sound is heard, do not press any further.

- Remove the gauge and read the belt tension by observing the point where the top side of the blue indicator arm crosses the numbered scale on the gauge body.

- Care must be taken to ensure that the gauge is not 'rocked' when pressing down on the blue pressure pad. The strap above the pressure bar is provided to attach snugly over the finger and prevent any 'rocking' motion.

- Due to the fact that this device requires some amount of practice and operator skill, the accuracy and repeatability of the tension readings are not high.

- Improvement

- Because this procedure is not trivial to perform consistently, there is a modification to make the tension gauge easier to align

- Gates' Carbon Drive mobile app

- As of 2017, the Official Owners Manual also includes a procedure using Gates' Carbon Drive mobile app to check belt tension.

- Usage

- Use the application in a quiet environment.

- Pluck the belt near the center of the lower belt span, so it vibrates like a guitar string.

| Belt Type | Years | Resonant Frequency | Tension Range |

|---|---|---|---|

| Narrow | 2013-2016 | 96.3 Hz – 124 Hz | 20 – 30kg |

| Wide | 2017+ (except S 13.0) | 42.5 Hz – 73.6 Hz | 25 – 76.5kg |

The frequency can also be checked with instrument tuning apps such as Tuner-gStrings for Android.

Belt Adjustment

FST Platform/Drive Belt Adjustment

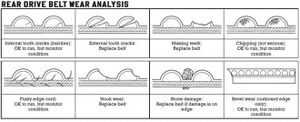

Belt Wear

Generally, watch for belt damage and try to anticipate when to replace the belt to avoid an incident on the road where the belt snaps.

- What to Check

- Check the teeth for wear and cracks.

- If you see cracks in the tooth forming, the belt is getting old.

- If you see deep cracks starting, it's time to replace the belt ASAP.

- When to Replace

- When it snaps.

- When any teeth have been ground off.

- Hard Skips

- If the belt experiences a "hard skip" from debris between the belt and a sprocket, it is likely to fail soon after. Watch it carefully if this happens.

- Tension with aging

- Apparently, per forum user JaimeC, belts don't wear like chains.

- As they get older they'll actually get tighter, not looser like a chain.

- When a chain ages, the little bearing points between the links and rollers wear causing the chain to hang looser.

- When a belt ages, the rubber on the inner/toothed side begins to swell.

- Since the Kevlar belt on the outer circumference won't stretch, the inner circumference will shrink making the belt tighter around the sprockets.

- Generally, you want to make sure the belt hasn't gotten any tighter since you brought it home.

- References

Belt Replacement

FST Platform/Drive Belt Replacement Procedure

Sprocket

Sprocket Specifications

| Belt | Front | Rear | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Width | Pitch | Years | Models | Teeth | Depth | Bore | Other | Teeth | Depth | Bore | Other | Ratio |

| 14mm | 8mm | 2012-2016 | SR | 30 | 15mm | 1" | key measurements? | 130 | 15mm | 1" | 4.33:1 | |

| FX/FXS | 25 | 132 | 5.28:1 | |||||||||

| S/DS/DSR | 28 | 130 | 4.64:1 | |||||||||

| 2017-2018 | S 13.0 | |||||||||||

| 17mm | 11mm | FX/FXS/DS/DSR/SR/S6.5 | 20 | 17mm | spline measurements? | 90 | 17mm | 4.50:1 | ||||

| 2019 | S/DS/SR/DSR/FX/FXS | |||||||||||

Sprocket Wear On Belt

Wear debris from the tire or the road can accumulate on sprocket teeth, putting pressure on the belt which can wear it out faster.

- Recommendation

- Keep the sprocket teeth clean to minimize wear on the belt.

- A non-abrasive brush should be effective.

Front Sprocket Removal / Swap

Removing or replacing the front sprocket on S and X platforms.

- Video Guide

Some guidance from Terry in this motor removal thread:

- Basically, if you are doing this to try to get more acceleration by moving from a 28 tooth to a 25 tooth, Harlan recommends trading in the DS on a 2015+ SR or 2016 DSR if you need the off road capabilities. You will get much much more acceleration and not hurt your top end performance.

- On the drive belt side, the upper rear 5mm bolt takes extreme care to remove. It is tapered to locate the motor. There is a very strong chance of stripping the head and have to drill it out. Make sure to have a machine shop close by just in case.

- On the other hand, removal of the motor may not be necessary.

- The other 7 bolts, 3 on the sprocket side and 4 on the rear brake side are the only thing simple and straight forward.

- You will need a special 3" or longer 6mm allen head socket for sticking in the hole through the frame at the front of the motor.

- Remove the rear brake pedal and assembly to get the heel guard out of the way of the top right rear motor bolt.

- Be careful not to strip these bolts either.

- They have Loctite; use a torch.

- And make sure your local hardware store has these replacement bolts handy in case you have to drill them out.

- The rear brake pedal needs to move anyway to get the right swingarm bolt out.

- Also the sprocket bolt itself, as well as removing and installing the new sprocket on the shaft can be very difficult. Some of the best professionals have had trouble.

- Loctite has been used on everything and you will need a torch to remove them.

- Even so, you will need a strap wrench with an old belt as the strap to hold the sprocket and a high power impact wrench.

- Even with all that right, you have a chance of stripping or breaking the bolt. The sprocket is pressed pretty tight.

- Be very careful not to permanently damage the motor bearings by prying between the motor itself and the sprocket to try to remove it, and also by tapping with a hammer to try to fit the new one on. You will be tempted to do both, but you need to find another way.

- A gear puller would be much better.

- There are other things to watch for:

- Mark your phase leads and pay special attention to the routing.

- Don't over-tighten the motor jack nuts and bolts until you have the swingarm back in place as it can pull the frame together slightly making it impossible to get the swingarm in place.

- Make sure you unplug the 8 way motor encoder harness and it doesn't get yanked and pull a wire.

- The top shock mounting bolt is a 15 and 17 mm and can be done with ratchet wrenches 1/32 of a turn at a time, or without ratchet wrenches if you are known to have extreme patience. It can take a while. The 2014 is a little easier and is (seems to be a) dual 17mm bolt and nut.

- The swingarm bolts are 10mm allen head and can be extremely hard to relocate even when working with someone else, a rubber hammer, and a flashlight. Those who have replaced their own belt before can vouch for this.

- Again, I doubt too many on this forum have done this, and those who did I'll bet agree with me that it makes more sense after they did it and perhaps had their bike out of commission to work through the things that didn't go right, and would agree to just upgrade to the SR or DSR first vs trying to change the front sprocket.

- Also the 25 tooth sprocket will break belts easier as less teeth are engaged than the 28 tooth, which can make it more likely to sheer teeth in the event of a wheelspin, and it bends the belt at a sharper radius which can possibly fatigue the carbon strands more. The SR actually uses a 30 tooth front sprocket which is even nicer to the belt than the 28 tooth.

Brakes

Brake Maintenance

- Check for pad wear or debris.

- Keep the pads and discs clean.

- An occasional brushing of the disc holes is worth doing maybe once a year.

- Check hydraulic fluid level.

- Make sure the brake fluid is in good shape and the type/specs you need.

- If in doubt, replace with fresh fluid (not from an already opened bottle).

- Make sure the brake fluid reservoir is not over-filled (top).

- There has to be some empty space, or your bike will be lightly "braked" and your disk/pads will deteriorate prematurely...and you will get less range.

Brake Systems

| Front | Rear | ||||||

|---|---|---|---|---|---|---|---|

| Year | Manufacturer | Rotor | Caliper | Manufacturer | Rotor | Caliper | Notes |

| 2013 | Nissin |

|

Nissin | 221mm ⌀

|

relatively weak

J Juan upgrade available for rear brake. | ||

| 2014 | J Juan | 240mm ⌀ |

|

Same pad sizes as 2013. | |||

| 2015 | J Juan |

|

|

Bosch Gen 9 ABS; New pad sizes. | |||

| 2016 | Bosch Gen 9 ABS | ||||||

| 2017 | |||||||

| 2018 | |||||||

| 2019 | |||||||

| 2020 | |||||||

Brake Hydraulics

| Models | Front | |||

|---|---|---|---|---|

| Platform | Years | Caliper Piston Area | MC Piston Area | Hydraulic-Advantage Ratio |

| S | 2015 | 1509 mm² (total) | 126 mm² | 11.9:1 |

| 2016 | ||||

| 2017 | ||||

| 2018 | ||||

| 2019 | ||||

| 2020 | ||||

- Regarding Brake Upgrades:

- A 9.5mm-piston master cylinder - like the Nissin 3/8 I put on my 'MX' bike - would give the SR a 21.1:1 ratio, or @ 78% more pad pressure than the OEM 12.7mm master cylinder.

- Any Brembo, Nissin, etc. 9.5mm / .375" master cylinder w/switch should drop right in and make a huge difference, and you won't have to touch anything else.

- On the rear, the 11mm master cylinder from the FX (Zero part# 25-06731) has 49mm M6 bolt spacing / rear reservoir hose / top output / clevis, and should give @ 19% more pad pressure than the SR 12mm master cylinder.

- This won't be a night-and-day difference like the front master cylinder change, but it should still be very noticeable.

Rear Brake Actuator

FST Platform/Rear Brake Actuator

ABS System

2015+ models have a Bosch ABS system installed.

ABS Unit

ABS Wheel Sensors

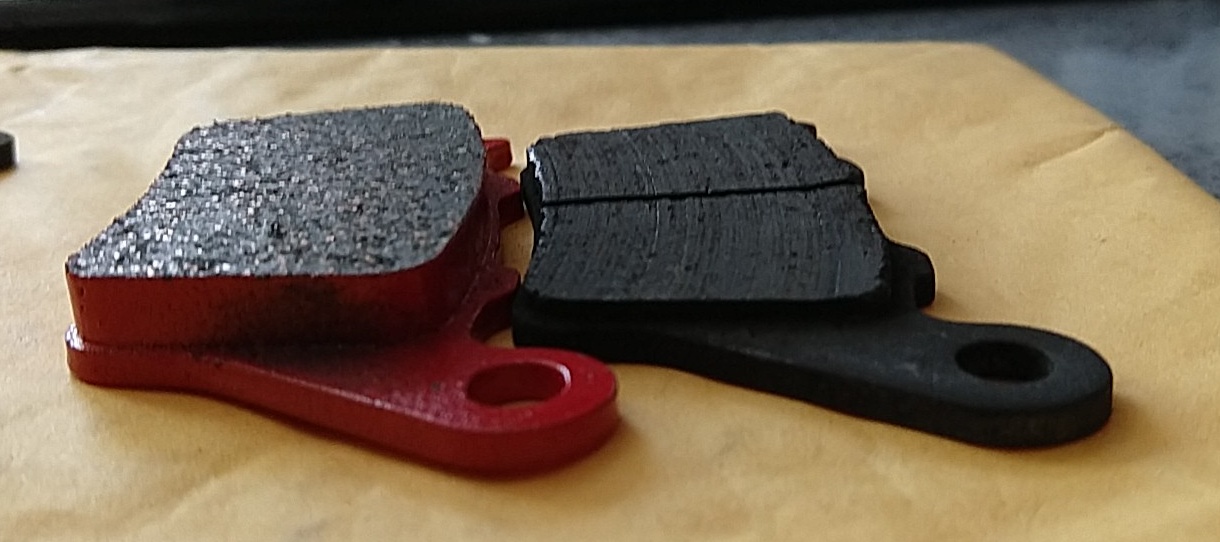

Brake Pads

Zero Motorcycles models use disc brakes with consumable brake pads applied by calipers to the rotors.

- General Reading Material

- Top 10 Questions About Motorcycle Brake Pads

- Motorcycle Brake Pads & Rotors Explained, by Galfer USA

- Sintered vs Organic Brake Pads

- General Brake Pad Replacement Suggestions

- 2013+ (Gen2, Gen3): Try to not use synthetics pads or "sintered", but organic or semi sintered ones.

- Sintered are better for very aggressive riding/braking, but are generally noisier.

- 2012 and earlier (Gen1): Keep the sintered pads

- Brake pump is very weak on these models; you need all the braking power you can get in spite of noise.

- Sand the pads.

- Grease the back of the pads lightly with ceramic grease (copper grease can interfere with ABS sensors).

- Check caliper position.

- Check caliper springs, if any.

- Check the wheel for trueness.

- Sand the disk; it could have lightly crystalized.

- Make sure all the bolts in the system (including wheel) are properly tightened.

- After all of this has been preformed and before riding, clean everything exposed to dirt/grease with isopropyl alcohol

- When riding again, try to not brake very aggressively the first 20-30 miles.

Brake Problems

This covers general problems with brake pads, in terms of typical symptoms.

- Brake Squeak

- Brake squeak (pad front against the disc) happens occasionally and is relatively quiet and noticeable but not anomalous.

- Brake Squeal

- Brake squeal (pad back resonating against caliper cylinder) can be very loud and annoying. Squeal does not technically impact performance but it's very unpleasant and might cause the rider to hesitate before fully braking which is a safety issue.

- Solutions

- Clean the pads and/or discs for squeaking.

- Try a different brake pad (attractive if you want a different pad feel or performance in the first place).

- LocTite Disc Brake Quiet stick applicator for the backs of the pads.

- Chamfer the brake pads

- File the edges of the pad to put a 45 degree edge on them

- You only need 1-2mm

Brake Pad Fit

- Nissin (2013 on rear, and 2013/2014 front)

- J Juan (2014+ on rear, 2015+ on front)

- Front pad shape FDB892

- Rear pad shape FDB539

Past forum threads of highly varying quality / ability to clarify:

- This forum discussion starts with the 14FX and brings up lots of issues.

- Another forum thread on brake pad alternatives to OEM/stock.

- One exhaustive listing from Burton which unfortunately have the wrong EBC fitment numbers.

- EBC

- The EBC brake catalog covers Zero models.

- However, it has always had the wrong shape recommendation for 2013-2014 models, and for the FX entirely! Double-check any recommendation.

- Their Carbon X pads can eliminate front brake squeal. EBC Carbon X page

- SBS

- offers a brake search engine which covers Zero models.

- Goldfren

- offers a good cross reference between brands.

- Brembo

- Brembo's Motorcycle Brakes Configurator has reasonably usable Zero model lookup.

- Their Carbon Ceramic pads are reported to resolve brake squeal issues.

Front Brake Pad Replacement

See Brake Pad Lookup to ensure a brake pad match.

| Avoid touching the pad and rotor surfaces with sharp tools and anything dirty or greasy. Avoid applying one-sided pressure to the rotor. |

- 2013-2014 S-platform

- Actual bike used was a 2014 SR (Nissin 313mm). Likely applicable to S/DS/DSR.

- Tools

- 13mm hex socket

- Torque wrench

- 4mm Allen key

- Size 1 flat head screwdriver

- Sandpaper

- Brake cleaner

- Ceramic grease (copper grease can interfer with the ABS sensors)

- Steps

- Clean the slave cylinder to prevent forcing damaging detritus into the seal.

- Gently force the brake pads away from the disk, to ensure room for the new pads, which will be thicker than the worn pads.

- Apply pressure evenly by hand or with a soft-surfaced tool.

- Pre-2015: Using the Size 1 flat blade screwdriver, remove the cap to expose the head of the pin.

-

Warning:

Warning: Penetrating oil may be necessary, and it's important to use the right size flat blade, as smaller ones can strip the slot as you apply pressure. -

Warning:

Warning: Rely on the caliper bolts' anchoring to the disc to ensure leverage.

-

- Remove the pin using a 4mm Allen key.

-

Warning:

Warning: Rely on the caliper bolts' anchoring to the disc to ensure leverage.

-

- Remove the 13mm hex bolts holding the caliper to the fork bracket.

- Remove the caliper from the brake disc; inspect and clean.

- It may be possible to change the brake pads without removing the calipers from the disk, but removal is more thorough to check for wear and keep it clean.

- Remove the plate with the brake pads, inspect and clean, and put in fresh pads.

- Apply ceramic grease to the slave cylinders and sand the front surface of the pads.

- Re-install the pin through the brake pads to anchor them in place.

- Apply a drop of blue Loctite to prevent it coming loose.

- Re-install the calipers against the rotor:

- With the pads separated sufficiently, slide the caliper over the front disc.

- Align the caliper mounting holes with the fork bracket and thread the 13mm hex bolts to hold in place.

- Apply some blue Loctite to each caliper mounting bolt and tighten with the 13mm hex socket to the right torque (2014+: 19ft-lb, 2013: 12ft-lb).

- Pre-2015: Using the Size 1 flat blade screwdriver and a drop of blue Loctite, re-install and tighten the cap over the head of the pin.

- Squeeze the front brake lever a few times to build up pressure in the hydraulics and press the pads up to the disc.

- Test the brakes

- Rotate the front wheel to check that the caliper doesn't impede the wheel.

- Roll the bike and test the brake lever action.

- If there are no obvious problems, gear up and slowly ride the bike to test the brakes.

- If possible, gradually increase the speed of the braking tests to seat and smooth the pads.

- Perform an initially very slow test ride (walking speed up to 25mph), checking brake function and ensuring they are seated and performing adequately.

- 2015+ S Platform

- Actual bike used was a 2016 SR

- Locate the bolt used to pin the low side of the brake pads.

- Remove the clip on the inside of the bolt.

- Detach the ABS wire from the brake line, by carefully unclipping the lower three fasteners holding the ABS wire to the brake line.

- Remove the bolt pinning the pads with a #25 Torx bit.

- Back out the caliper bolts with a 8mm hex bit on a 12-inch or longer wrench.

- Remove the caliper from the rotor.

- Complelely remove the caliper bolts and slide the caliper as far as possible off the rotor.

- With a flat screwdriver about 8-inches long, drop the inside pad out of the caliper.

- After the inside pad clears the caliper, remove the caliper.

- Temporarily hold the old pads against the pistons by loosely replacing the bolt that pins the pads.

- Fully push back the pistons, by using a C-clamp with at least 2x2-inch opening and 1-inch heads, clamping the old pads to the outside caliper body.

- Remove the clamp and old pads.

- Test fit the new pads.

- Insert the outside pad in the caliper.

- Hold the caliper against the rotor and insert the inside pad.

- Re-install the calipers against the rotor:

- Position the caliper to insert the caliper bolts, and tighten a little more than finger-tight.

- Carefully drive the pad-pinning bolt until it stops, and reinstall the inboard clip.

- Remove the caliper bolts one at a time, apply Loctite 242 or equivalent, and retighten.

- Torque the caliper bolts to 19 lb-ft (26 Nm).

- Re-attach the ABS wire to the brake line (via the 3 clips).

- Squeeze the front brake lever a few times to build up pressure in the hydraulics and press the pads up to the disc.

- Test the brakes

- Rotate the front wheel to check that the caliper doesn't impede the wheel.

- Roll the bike and test the brake lever action.

- If there are no obvious problems, gear up and slowly ride the bike to test the brakes.

- If possible, gradually increase the speed of the braking tests to seat and smooth the pads.

- Perform an initially very slow test ride (walking speed up to 25mph), checking brake function and ensuring they are seated and performing adequately.

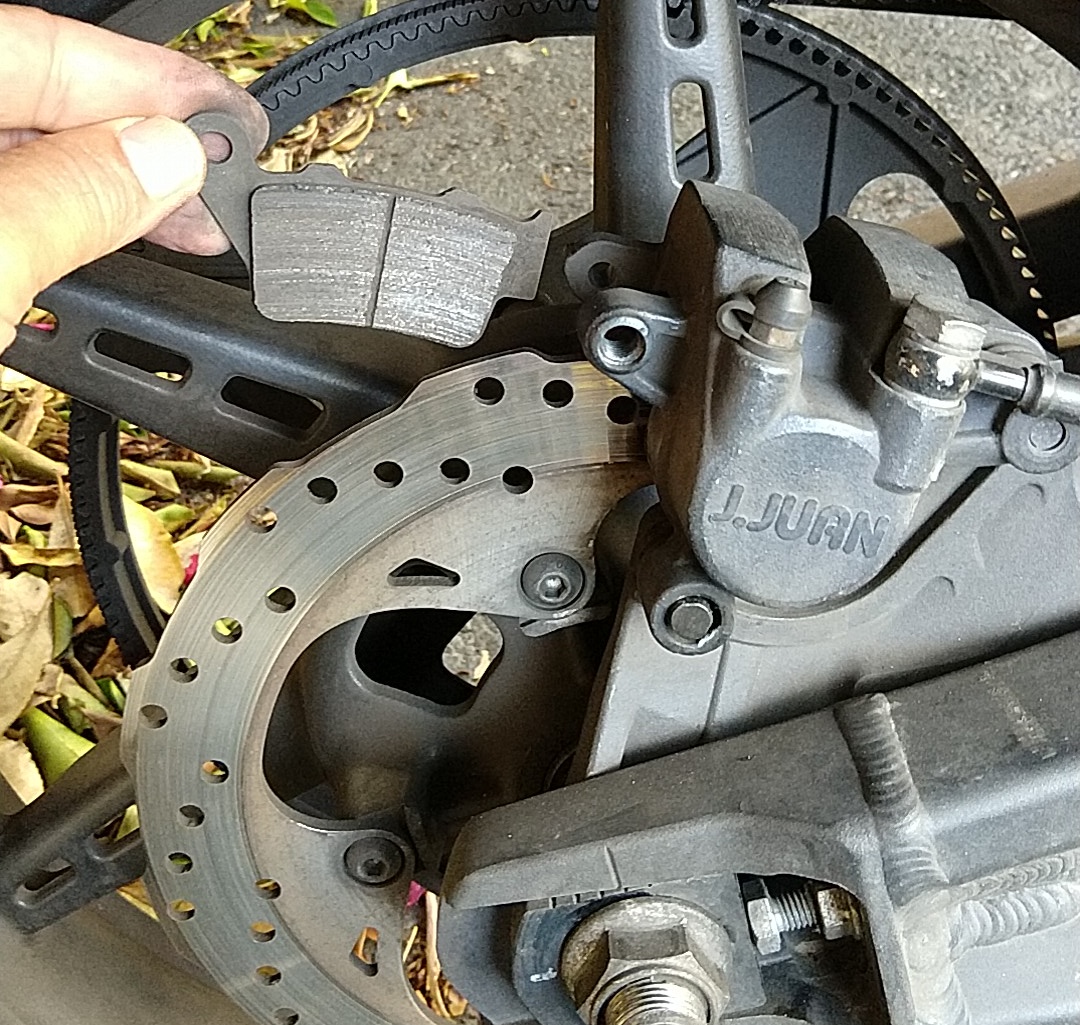

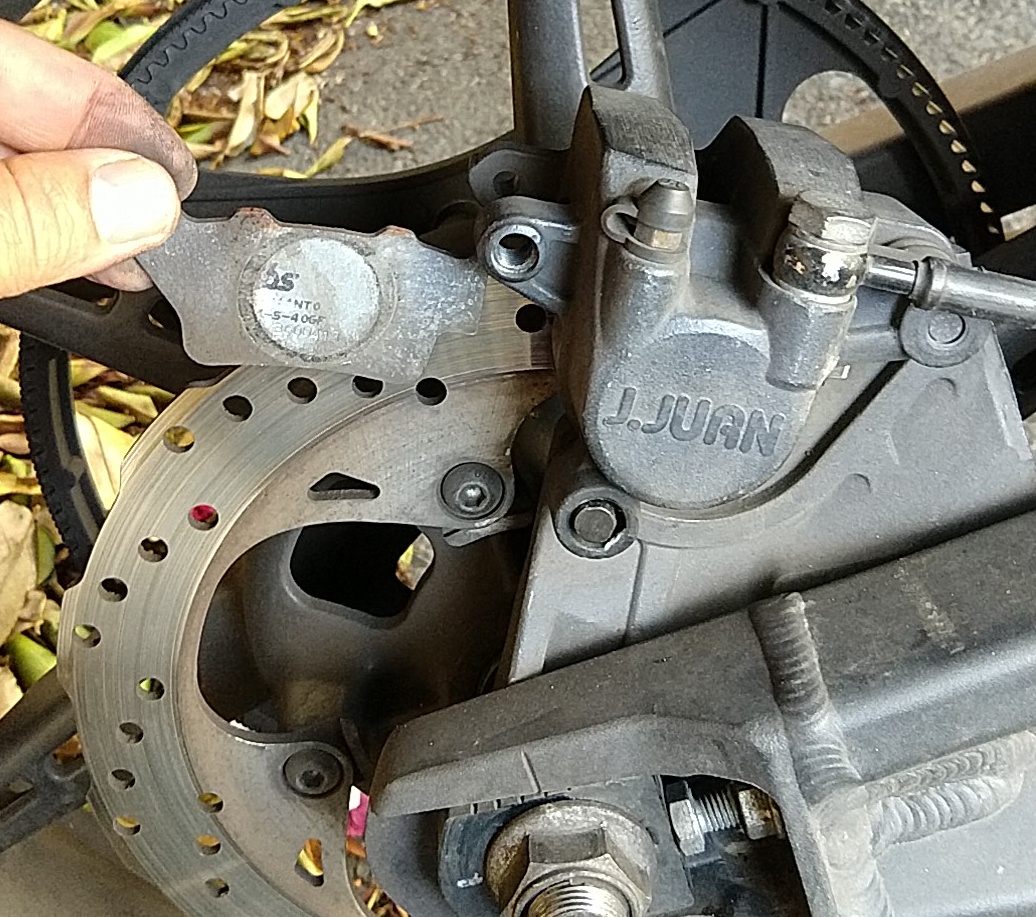

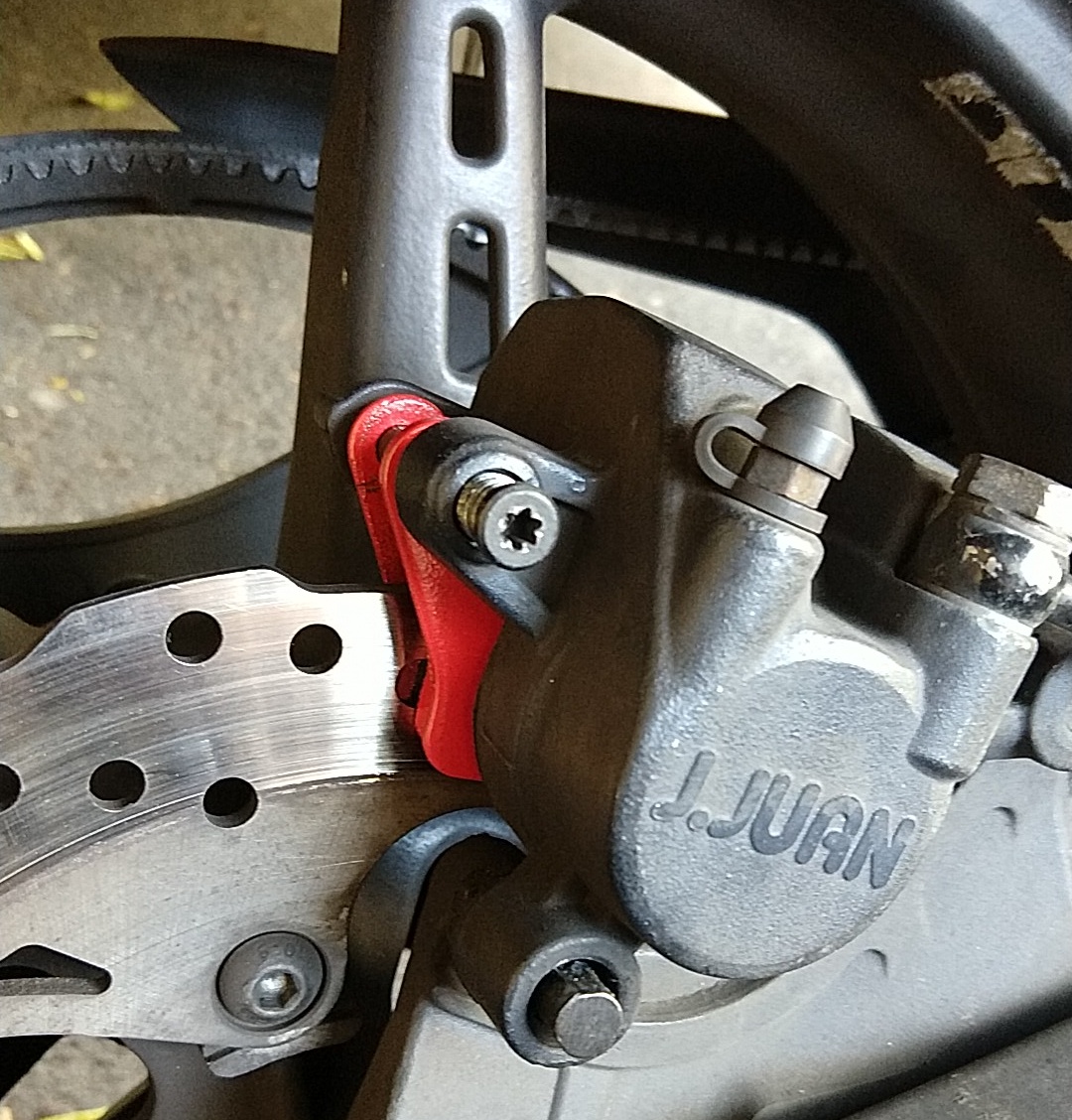

Rear Brake Pad Replacement

- Tools

- T25 Torx bit screwdriver

- Flat blade screwdriver

- Small pliers

- 200 grit sand paper (optional)

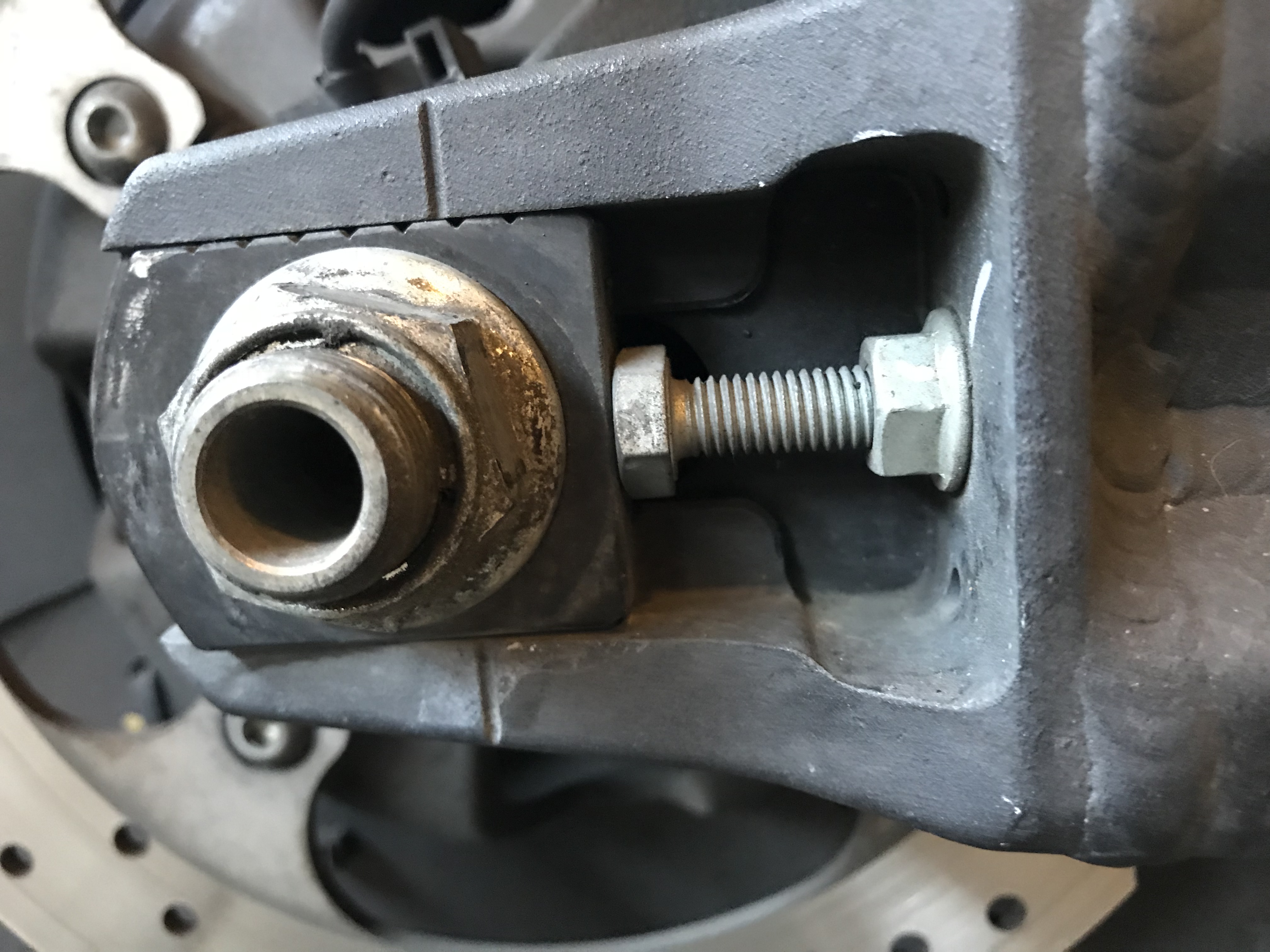

- Remove safety spring-clip from the rear of the bolt (on the side of the wheel).

- Remove the bolt that goes through the "eye" of the brake pads (using #25 torx driver).

- Pull out the pads.

- If there's any debris like paint on the pad material, you may want to sand them flat/clean gently over some 200 grit sandpaper on a flat surface.

- Put in new pads.

- Screw-in the bolt.

- Reinstall safety clip.

- Test your ride carefully!

- References

- Per Rear Pad Replacement for J Juan rear brakes (2014+)

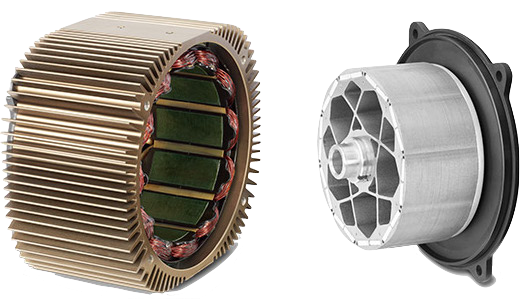

Powertrain

The powertrain includes all of Zero's power storage and delivery components including the battery, but this section focuses on the motor, power delivery via the controller, and their inputs via throttle and drive mode configurations.

- Licensing

- For a time, Zero openly offered powertrain components in a licensed manner for prototyping and other uses.

- Currently, probably for reasons of liability and support overhead, this is not publicly offered but does seem available on request for companies wanting to develop products where Zero's powertrain is a good fit.

- See Zero's Z-Force Powertrain Solutions page which has a contact form.

Throttle

The Zero throttle is a very straightforward twist-grip motorcycle control that operates a sensor instead of pulling on a mechanical cable or operating hydraulics.

Zero switched the throttle supplier from a Magura with a linear potentiometer to a Bitron with a Hall-effect sensor in 2015 which changed how the wiring works.

- Connections

- The Zero throttle connects directly to the controller, so anything you do related to the throttle signal can compromise the operation of the bike if there's an electrical fault or discrepancy.

- Example: Sudden braking followed by no motor/throttle response on highway[2016 FXS]

- Customization

- See Drive Modes to customize throttle input interpretation as an owner.

- Use the mode control for "Custom" mode on 2014+ or "Eco" on earlier models to set the maximum torque the throttle applies.

- This also directly changes how quickly torque ramps up for a given throttle twist/position.

- Advanced Customization

- The Sevcon motor controller settings are where most of the throttle interpretation happens.

- Replacement

- TODO...

- Assembly

- The return spring cannot be tensioned while disassembled throttle is on the handlebar. Throttle must be removed to place the spring end correctly. see video from Harlan Flagg: https://www.facebook.com/harlanflagg/videos/1364143910276196/

- Troubleshooting

- One report of a "snatchy" throttle turned out to have this explanation:

- There is a black adjusting screw which holds the pinion gear of the throttle in place or for adjustment.

- The pinion gear had moved to the right and caused the spring clip for throttle return to pop out of the slot.

- This was clicking through the gears and causing a notchy throttle feel.

- Resolution: Reset the pinion location and tighten the screw.

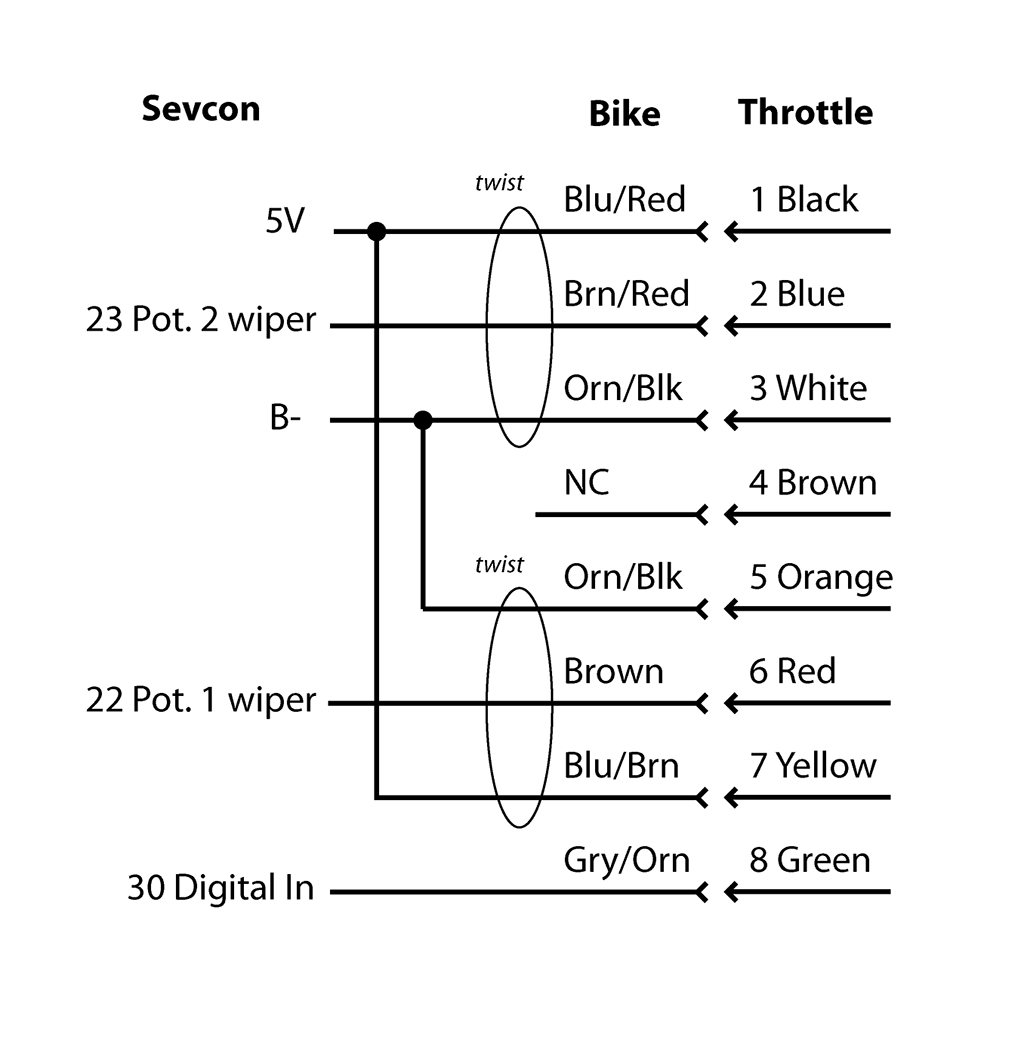

Bitron Throttle

2015+ models use a new HAL-based (Hall-effect active device) sensor from Bitron which can't be replaced easily by Domino or similar

- Product reference: Bitron HAL-based throttle

- Connectors

- Via Keith's investigation

- 8 wire output, bundled into two pairs of 3 wires for potentiometer outputs.

-

- Sumitomo connector 6188-0779

- Sumitomo connector 6189-1240

- The hall-effect sensor may be a potentiometer wired up as a voltage divider as follows:

| Wire | Twist | Voltage |

|---|---|---|

| Brown | None | 0.5 |

| Full | 4.5 | |

| Brown/Red | None | 4.5 |

| Full | 0.5 |

Regen

Drive Modes

The Zero platform has always offered a simple control for switching throttle and regen mappings through MBB-Sevcon interaction.

- Gen1 (2009-2013)

- Through 2013, only Eco and Sport modes were available, where Eco was the customizable mode but had the Eco default as listed below.

- The modes are selected with a rocker switch on the left part of the steering head bracket forward from the handlebars.

- Gen2 (2014-)

- 2014 models introduced a separate Custom mode and made Eco mode fixed.

- Modes are selected by pressing a selector button on the right hand switch assembly; the selected mode then activates when the throttle is released for a couple of seconds.

- The SRF Model introduced "Street, Sport, Eco, Rain and up to 10 programmable custom modes".

- Custom traction control modes were also introduced.

| Mode | Max Speed | Max Torque | Max Regen | Max Regen Brake |

|---|---|---|---|---|

| Eco | 70 mph | 40% | 66% | 100% |

| Custom | 70 mph | 100% | 40% | 66% |

| Sport | 98 mph | 100% | 40%? | 66%? |

- Gen2 Customization

- Many riders make their own Custom mode settings. There are many options that all involve tradeoffs.

- 0% (-20%) Max Regen

- This enables a "coasting" mode which is very efficient, in allowing the rider to let the bike's momentum carry it forward for a while.